Finding the Best Extendable Ladders in the UK: A Bison Products Guide

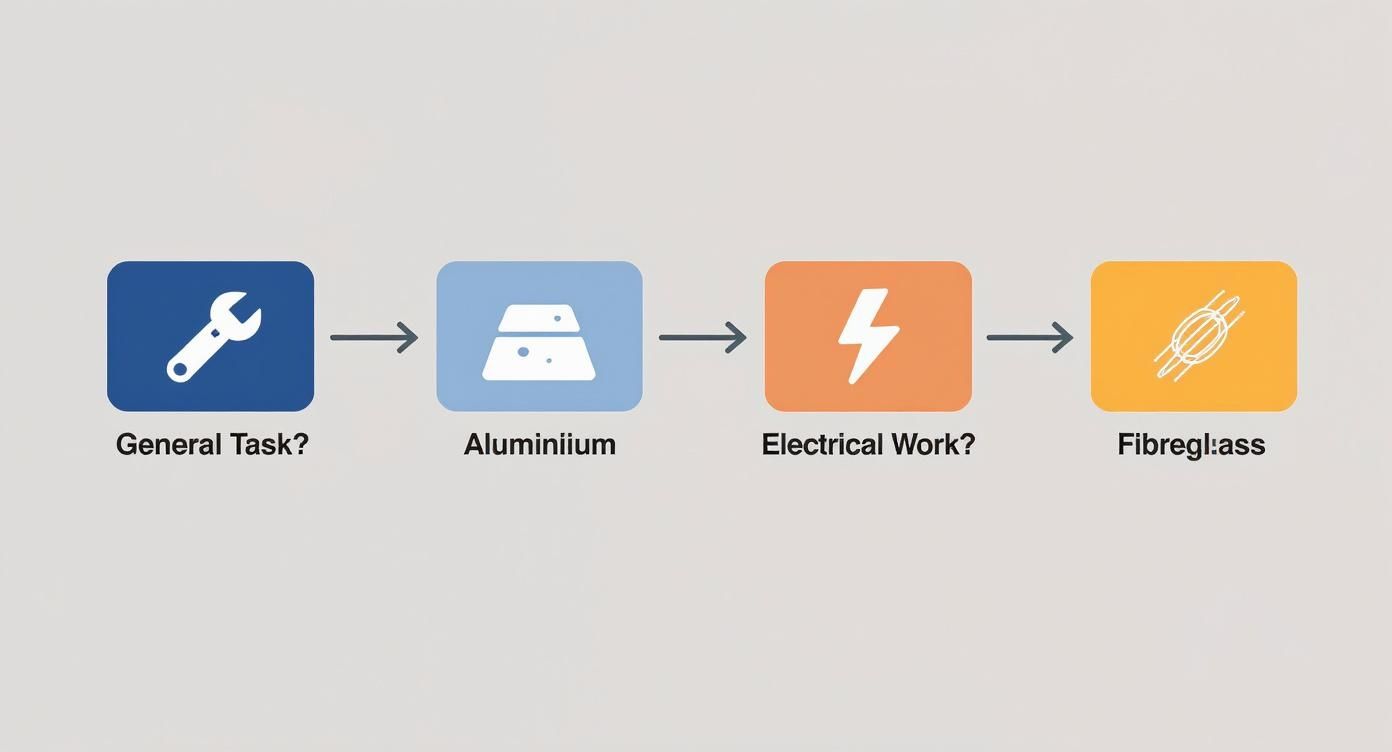

Choosing the right extendable ladder can feel a bit daunting, but here at Bison Products, we’ve learned a thing or two since we started back in 1972. The best extendable ladders always nail the balance between the right material for the job and certified safety standards. For most DIY tasks around your home, a lightweight aluminium ladder is usually spot-on. However, if you're a professional working anywhere near electrical hazards, you absolutely must opt for non-conductive fibreglass.

Whatever you're leaning towards, the most critical factor is that any ladder you buy in the UK meets the EN131 safety standard. As a family-run British business, your safety is our top priority, and that starts with certified equipment.

Your Starting Point for Choosing the Right Ladder

Trying to navigate the world of extendable ladders can feel like a real minefield. With all the different materials, heights, and features on offer, how can you be sure you’re making a safe, smart choice? This guide is here to cut through the confusion and help you confidently pick a ladder that will be a reliable workmate for years to come.

Whether you're a seasoned tradesperson who needs a tough, British-made tool for daily graft or a weekend warrior tackling home maintenance, the basic principles of choosing a ladder don't change. It all comes down to matching the tool to the task, safely and efficiently.

Key Factors to Consider

Before you even start looking at specific models, it pays to take a moment to think about what you actually need. A good decision always starts with asking the right questions.

-

What kind of work will you be doing? Are you painting walls, clearing out gutters, or maybe tackling some electrical work? The job really dictates the material.

-

How high do you really need to reach? This is about figuring out your safe working height, not just the ladder's overall length. Getting this wrong leads to dangerous over-reaching.

-

What's the total weight it needs to hold? Don't forget to add up your own weight plus any tools and materials you'll be carrying up with you.

Getting a clear picture of these factors is the essential first step towards a confident purchase. If you're also exploring other ways to work at height, you might find our guide on choosing a step ladder with a handrail useful, as it looks at options built for extra stability.

The UK ladder market is a huge part of a wider industry, showing just how strong the demand is from industrial, commercial, and home users alike. It's interesting to see that many UK industrial clients are now insisting on extension ladders with advanced safety features, sometimes pushing the price for a single unit over £500.

Your ladder isn't just another tool; it's a critical piece of safety equipment. Investing in a quality, certified product that fits your specific needs is one of the most important decisions you can make for any project at height.

Choosing Your Ladder Material: Aluminium vs Fibreglass

The first big decision you'll make when picking an extendable ladder is the material. This choice has a massive impact on everything from safety and durability to how easy it is to lug around day-to-day.

For most homeowners and tradespeople here in the UK, an aluminium ladder is the default choice, and for good reason. It’s incredibly lightweight, which makes a world of difference when you’re carrying it around a property or hoisting it off the van roof. Aluminium also stands up brilliantly to rust – a must-have feature given our famously unpredictable British weather.

This blend of portability and weather resistance makes it a fantastic all-rounder for general jobs. We’re talking about tasks like clearing out gutters, slapping a new coat of paint on exterior walls, or trimming back those overgrown hedges. For scenarios like these, the sheer practicality and value for money of aluminium are hard to beat.

When Fibreglass is Non-Negotiable

But, and this is a big but, there’s one situation where aluminium is absolutely the wrong tool for the job. If you’re going to be working anywhere near electrical wires or potential power sources, you must use a fibreglass ladder.

Aluminium is a fantastic conductor of electricity. One accidental touch against a live wire could lead to a catastrophic electric shock. Fibreglass, on the other hand, is completely non-conductive. It provides a life-saving barrier of protection. This single property makes it the only sensible and safe option for electricians, telecom engineers, or anyone doing maintenance near overhead power lines.

"Safety should always be the deciding factor. While an aluminium ladder is perfect for 90% of jobs, the 10% involving electrical hazards demand the non-conductive properties of fibreglass. It's a simple choice that prevents catastrophic accidents."

Comparing Key Characteristics

Beyond the crucial electrical safety aspect, there are a few other differences to keep in mind. Fibreglass ladders tend to be heavier and more rigid than their aluminium cousins. While this can make them a bit more of a workout to move around, it also means they are incredibly tough and resistant to dents and bending. They also don't get hot to the touch, which is a nice little bonus on a rare sunny day.

To make things clearer, let's break down the key differences.

Aluminium vs Fibreglass Ladders At a Glance

Here’s a quick comparison to help you weigh up which material suits your needs best.

| Feature | Aluminium Ladders | Fibreglass Ladders |

|---|---|---|

| Conductivity | High (Unsafe for electrical work) | Non-conductive (Essential for electrical work) |

| Weight | Lightweight and easy to transport | Heavier and more robust |

| Durability | Rust-resistant but can dent | Weather-resistant and very strong |

| Cost | Generally more budget-friendly | Typically a higher initial investment |

| Best For | General DIY, painting, roofing | Electrical work, utility maintenance |

Ultimately, the choice between these two excellent materials boils down to the reality of your work environment. Take a moment to honestly assess the kinds of jobs you'll be tackling. That way, you can confidently pick the ladder that gives you the right mix of practicality, durability, and—most importantly—safety for the task at hand.

Calculating the Right Ladder Height and Capacity

Picking a ladder that’s too short is one of the easiest—and most dangerous—mistakes you can make. It’s tempting to just glance at the fully extended length on the box, but the number you really need to care about is the safe working height. This is the height you can comfortably reach without stretching or, even worse, standing on the top few rungs. Never stand on the top few rungs.

Getting this right is all about preventing accidents before they happen. Let's say you're clearing the gutters on a standard two-storey house. You don't just need a ladder to reach the roofline; you need it to go about a metre (or three rungs) past it. Health and safety experts recommend this because it gives you a solid handhold when you’re transitioning on or off the ladder. It makes a world of difference.

Finding Your Safe Working Height

So, how do you figure this out? A solid rule of thumb is to take the ladder's total extended length, subtract the length of the overlapping sections, and then add about 1.5 metres. That 1.5m is a good estimate of your own standing reach, giving you a far more realistic idea of what you can safely work on.

This simple flowchart can help you visualise the first few decisions you need to make based on the jobs you have in mind.

As you can see, while aluminium is brilliant for most general tasks, the moment any electrical work is involved, fibreglass becomes the only sensible and professional choice.

Understanding Weight Capacity and Duty Ratings

Just as important as the height is the ladder's weight capacity, which you'll see referred to as its 'duty rating'. This isn't just about your body weight. You have to account for the total combined weight of you, your tools, and any materials you might be lugging up with you. A heavy drill or a full bucket of paint adds a surprising amount of load.

In the UK, ladder ratings are all about the EN131 standard. There are two main classes you'll come across:

-

EN131 Professional: These are built tough for frequent, heavy-duty use on commercial job sites. They go through more rigorous testing and have a maximum load of 150kg.

-

EN131 Non-Professional: This class is designed for occasional domestic jobs. While they also have a maximum load of 150kg, the testing isn't quite as demanding to reflect their lighter intended use.

Even if you're just using it around the house, splashing out on an EN131 Professional ladder is a smart move. That extra durability and robust build quality give you incredible peace of mind and ensure it'll last for years. It's what separates a good ladder from one of the best extendable ladders you can buy.

Always go for a ladder with a capacity that’s comfortably more than what you think you’ll need. That extra margin is a critical safety buffer. It accounts for any unexpected loads and ensures you never compromise the ladder's structural integrity. It's a bit of foresight that protects both you and your gear.

Are Telescopic Ladders Right for You?

For anyone tight on storage space or constantly on the move, a telescopic ladder can feel like a revelation. If you’ve ever tried to wrestle a traditional extension ladder into a city flat or a packed work van, you’ll know exactly what I mean. It’s often just not practical.

Telescopic ladders solve this problem with an elegant design. They concertina down into a surprisingly small package, often compact enough to slide into a car boot or a cupboard under the stairs. This makes them a fantastic choice for mobile tradespeople tackling quick jobs, or for the DIY enthusiast who doesn't have the luxury of a garage.

How They Work and When to Use Them

The magic is in the locking mechanisms. As you extend the ladder, each rung slides out and should click firmly and audibly into place. That click isn't just satisfying to hear; it's a critical safety feature you must listen for every single time.

This clever design is catching on fast. The global market is set to grow by 7% annually from 2025, and a lot of that is driven by their appeal for UK homes and construction sites where space is at a premium. The boom in home improvement projects has only made them more popular.

They really shine in situations where you need quick and easy height access without the faff of a bulky, heavy ladder:

-

Popping up into a loft hatch.

-

Changing a stubborn lightbulb in a high ceiling.

-

Clearing out the gutters on a single-storey bungalow.

-

Getting access to a client’s property on a street with zero parking.

The Other Side of the Coin: Potential Downsides

But let's be realistic—they aren't perfect for every job. While their portability is a massive advantage, the design has its own set of considerations. All those moving parts and locking pins demand a quick but thorough inspection before every single use. You need to be sure they're free of grit and haven't been damaged.

They can also feel a bit less rigid than a solid A-frame or a classic extension ladder, which might be unnerving if you’re not used to it, particularly at full stretch. It is absolutely vital to choose a model that is EN131 certified. The market has been flooded with some cheap, uncertified knock-offs that are frankly dangerous.

Telescopic ladders are a brilliant solution for specific problems, where portability and convenience are top priorities. Think of them as a specialist tool. If your daily grind involves working at maximum height and you need ultimate rigidity, day in and day out, a traditional extension ladder might still be your most reliable workhorse.

Whatever ladder you choose, using the right extras can make a world of difference to your safety and efficiency. Something as simple as a stabiliser bar can massively improve sideways stability. To see what’s available, have a look at our full range of professional ladder accessories.

Key Safety Features and UK Standards to Know

Right, you've sorted the material and height. Now we get down to the nitty-gritty: the safety features. These are the details that separate a reliable, long-lasting ladder from a risky purchase. Think of this as your final pre-buy checklist – these are the non-negotiables that prevent accidents and keep you safe up there.

First things first, look at the rungs. You want them to be wide with a deep, non-slip texture. This is absolutely crucial, especially with the classic damp British weather we all know and love. When your boots are wet or muddy, that extra grip is your first line of defence against a slip.

The Importance of Stability and Locking Systems

Another game-changer is the stabiliser bar. This is that wide bar you see at the bottom of most modern extendable ladders. Its job is simple but vital: it widens the ladder's footprint, making it far more stable and resistant to wobbling or slipping sideways. When you're reaching up high, that extra stability is incredibly reassuring.

Next up, get a good look at the locking mechanism. This is what holds the extended sections firmly in place, and you can't afford for it to fail. The best ones are robust, spring-loaded systems that click audibly and securely into place. You should also be able to operate it smoothly – extending and retracting the ladder shouldn't feel like a wrestling match.

Understanding the EN131 Standard

Here in the UK, the most important seal of approval you can find on a ladder is EN131 certification. This isn't just a sticker; it's a guarantee that the ladder has been put through its paces and tested for strength, stability, and overall durability. When you're tackling projects at home, proper safe ladder usage for roof access is non-negotiable, and using a certified ladder is the very first step.

The EN131 standard is broken down into two classes you'll come across:

-

EN131 Professional: These are built tough for the daily grind of a worksite and undergo more rigorous testing.

-

EN131 Non-Professional: This class is designed for DIY and home use but still has to meet high safety benchmarks.

This focus on safety is a massive deal in the UK market. The demand is for ladders that meet these strict regulations, which is why you see features like anti-slip rungs and stabilisers becoming standard.

A ladder without EN131 certification has no place on a job site or at your home. It’s a clear sign that it hasn't met the minimum safety requirements, and it’s simply not worth the risk.

Before you buy, and frankly, before every single use, give the ladder a quick once-over. Our guide on ladder inspection training has the full breakdown, but as a rule of thumb, always check for dents or cracks and make sure the feet are in good nick.

How to Maintain Your Extendable Ladder

Your extendable ladder isn't just a tool; it’s a critical piece of safety equipment. A little bit of care goes a long way in making sure it stays reliable for years to come.

Proper maintenance isn't some complicated chore. It's really just about building a few simple habits that protect your investment and, far more importantly, yourself. A well-maintained ladder is a safe ladder. Plain and simple.

Think of it like the MOT for your car. A quick check before each use can catch small issues before they snowball into dangerous problems. A ladder that's properly cared for will function smoothly, lock securely, and give you a stable base every time you need it.

Regular Inspection Checklist

Make it a habit to give your ladder a quick once-over before you even think about setting it up. This only takes a minute, but honestly, it's one of the most effective safety measures you can take.

You’re just looking for common signs of wear and tear that could compromise its integrity.

-

Check the Stiles: Scan the main vertical beams. Are there any dents, bends, or cracks? A dent might seem minor, but it can create a weak spot in the structure.

-

Inspect the Feet: The rubber or plastic feet at the base are absolutely critical for grip. Make sure they aren't worn down, cracked, or caked with mud that could cause a slip.

-

Test the Rungs: Give each rung a wiggle to ensure it’s secure. They should also be free from anything slippery like oil, grease, or wet paint.

-

Examine Locking Mechanisms: This is a big one for extendable ladders. Check that the locking catches engage fully and cleanly. They need to move freely without sticking or hesitation.

This simple routine is the foundation of ladder safety. If you want a more formal approach, our guide on using ladder inspection tags offers a great, structured way to handle official checks.

Cleaning and Proper Storage

Keeping your ladder clean isn't just about looking professional. All that grime, paint, and dirt can easily hide underlying defects like hairline cracks. After a messy job, just give it a good wipe-down with a damp cloth. Try to avoid harsh chemicals that could degrade plastic components or fibreglass coatings over time.

Storing your ladder correctly is just as important as cleaning it. Leaving an aluminium or fibreglass ladder outside, exposed to the elements day after day, is a surefire way to shorten its life.

The best place for it is somewhere dry and sheltered, like a garage or shed. Storing it horizontally on wall brackets is ideal. This stops it from bowing over time and keeps it safely out of the way. These simple steps ensure your ladder remains one of the best extendable ladders in your toolkit for a very long time.

Still Got Questions? We've Got Answers

Even after you think you've covered all the bases, there are always a few more questions that pop up. It's completely normal. Let's tackle some of the most common queries we get from customers, so you can feel totally confident in your choice.

What Is the EN131 Standard and Why Does It Matter?

Put simply, EN131 is the gold standard for ladder safety across the UK and Europe. If you see this certification on a ladder, it means it’s been through the wringer—rigorously tested for strength, stability, and overall durability.

It’s your assurance that you're buying a professional-grade tool, not some flimsy, dangerous knock-off. My advice? Don't even consider a ladder without it.

How Do I Set Up an Extendable Ladder Safely?

Getting the setup right is all about the angle. The easiest trick in the book is the 1-in-4 rule. For every four feet of height you climb, the base of the ladder needs to be one foot away from the wall. Simple as that.

This creates the perfect angle for maximum stability.

A common mistake I see all the time is people placing the ladder almost vertically against the wall, thinking it feels more secure. It’s a huge misconception. Doing that actually increases the risk of the base kicking out from under you. The 1-in-4 rule is your best friend here.

Can I Use an Extension Ladder on Uneven Ground?

Absolutely not, unless you have the right gear. Setting up a ladder on soft, bumpy, or sloped ground is just asking for trouble. It needs a solid, level footing to stop it from shifting or sinking while you're on it.

If you know you'll be working on a sloped driveway or a lumpy lawn, you’ll need to invest in some specialist ladder accessories. Things like a leg leveller or a heavy-duty ladder mat can create a safe, stable foundation. Whatever you do, never, ever just prop it up on a few bricks or a block of wood.

At Bison Products, your safety is our top priority. As a family business since 1972, we stand behind our range of British-made ladder accessories and EN131-certified ladders. We ensure you have the right, reliable equipment for any job, no matter how big or small. https://www.bisonproducts.co.uk